Woodworking in a Canadian Winter: How to Store and Protect Lumber

Canadian winters can be harsh, unpredictable, and unforgiving. From dry indoor air to heavy outdoor moisture, the cold season puts unique stress on wood and woodworking materials. Lumber that is not stored correctly can twist, crack, or develop mold long before the first signs of spring.

Whether you are a weekend hobbyist or a professional builder, understanding how wood behaves in winter and how to protect it properly is essential. With a few simple practices, you can keep your lumber flat, dry, and ready for your next project, no matter how cold it gets.

Understanding How Cold and Moisture Affect Wood

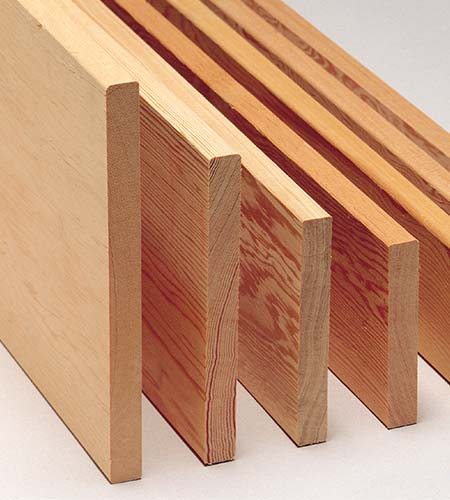

Wood is not a static material. It is a living, breathing substance that responds to the environment around it. As temperatures drop and humidity levels shift, wood expands, contracts, and sometimes absorbs moisture unevenly. The result can be visible warping, cupping, or surface cracks.

What Happens to Wood in Winter:

- Cold, dry air causes wood to lose moisture and shrink.

- Rapid changes between warm and cold environments can lead to cracks or checking.

- Moisture trapped under covers or near cold surfaces promotes mold and decay.

- Repeated freeze-thaw cycles weaken fibers and affect long-term strength.

In other words, winter is both drying and dampening at the same time. Heated indoor air can strip wood of moisture, while outdoor frost and condensation can soak it again. Knowing how to balance these opposing forces is the secret to protecting your lumber through the cold months.

Indoor Storage Methods for Lumber

Whenever possible, store lumber indoors where temperature and humidity are easier to control. A basement, heated garage, or insulated workshop provides the best environment for maintaining stable conditions.

Checklist for Proper Indoor Storage:

- Store Lumber Flat: Stack boards on a level surface to prevent bowing or sagging.

- Use Stickers for Spacing: Place thin spacers between layers of boards to promote even air circulation.

- Control Humidity: Maintain 35 to 55 percent relative humidity to keep boards stable.

- Avoid Direct Heat: Keep wood away from heaters or vents, which can dry it unevenly.

- Install Wall or Ceiling Racks: Use vertical or horizontal racks to save space and improve airflow.

- Monitor Conditions: A small digital hygrometer can help you keep tabs on moisture and temperature.

If you recently purchased new lumber, allow it to acclimate indoors for at least a week before cutting or joining. This gives the wood time to stabilize to your workspace conditions.

Outdoor Lumber Storage in Canadian Winters

Sometimes indoor storage simply is not an option. Many woodworkers and contractors must keep lumber outdoors during the winter months. While outdoor storage poses challenges, it can be done safely with the right preparation and attention to detail.

Using Tarps and Breathable Covers

Cover your lumber with a breathable material such as a canvas tarp or specialized outdoor lumber cover. Avoid plastic sheets or shrink wrap that trap condensation. Secure the top tightly but leave the sides open to encourage ventilation and prevent mold.

Elevating Wood Off the Ground

Never store lumber directly on concrete or soil. Moisture from the ground can quickly wick into the bottom boards and cause swelling or rot. Place your stacks on 2x4 runners, cinder blocks, or pallets to elevate them several inches off the ground. This allows airflow underneath and prevents ice buildup.

Covered Outdoor Lumber Storage Sheds

If you store wood outdoors often, consider building a small shed or covered shelter. A simple structure with a solid roof and open sides will block rain and snow while allowing good air movement. Keep stacks organized with stickers and label different species or thicknesses to prevent confusion later.

Workshop and Garage Storage Best Practices

Garages and workshops can be tricky spaces for storing lumber because they often fluctuate between warm and cold temperatures. To prevent damage, focus on consistency and airflow.

Keep your lumber stacks away from exterior walls, which can become cold and collect condensation. Use risers or shelves to keep wood off concrete floors and allow air to circulate underneath. If your workshop is heated, avoid positioning stacks directly in front of heaters or vents, since extreme heat can dry the boards unevenly.

Adding a small circulating fan or venting system can help maintain balanced air movement. If possible, insulate the garage or workshop to reduce humidity swings. Organized racks, bins, and clear labeling will also make it easier to find the right materials when the building season starts again in spring.

Preventing Warping, Splitting, and Mold

Most lumber damage happens gradually when air cannot circulate evenly or when humidity changes too fast. Preventing these problems is about creating steady conditions.

Top Prevention Strategies:

- Keep boards spaced evenly with stickers to promote airflow.

- Maintain stable humidity and temperature levels.

- Let new boards acclimate before working with them.

- Store boards of similar species and thickness together for even drying.

- Re-stack your lumber occasionally to relieve pressure and check for moisture.

- Inspect for early signs of mold and treat affected areas immediately with a wood-safe cleaner.

If slight warping or cupping occurs, restack the boards flat with weight on top. They often flatten naturally once moisture levels equalize. Avoid rushing the drying process with heat sources, as this can cause permanent cracks.

Preparing Lumber for Cold-Weather Projects

Even in winter, you can still build small projects indoors. Before working with stored lumber, take a few key steps to condition it properly.

Steps to Prepare Lumber for Use:

- Bring the Wood Indoors: Move boards into your heated space several days before use to prevent sudden moisture loss or gain.

- Allow Acclimation: Let boards sit until they reach the same temperature and moisture level as your workspace.

- Check Moisture Content: Use a moisture meter to ensure stability before gluing or joining pieces.

- Lightly Sand Surfaces: Sanding refreshes the grain and removes any raised fibers from temperature changes.

- Apply Finishes Correctly: Stains, sealers, and adhesives should only be applied in warm, dry conditions. Cold or humid environments can prevent proper curing.

By taking time to acclimate your materials, you will avoid common issues such as gaps, joint failure, and uneven finishes once your project is complete.

Woodworking in a Canadian Winter – Frequently Asked Questions

Does wood shrink in cold weather?

Yes. As air becomes dry and cold, wood loses moisture and contracts. When humidity rises again, it expands slightly.

What is the best way to store lumber outdoors in winter?

Elevate the stack, cover it with a breathable tarp, and leave the sides open for airflow. Make sure snow and water can drain away freely.

Can I store lumber in my garage during winter?

Yes. Keep it off the floor, away from exterior walls, and maintain good airflow. For best results, monitor humidity and avoid storing lumber near heat sources.

How do I keep lumber from warping over time?

Ensure proper spacing, stable humidity, and even air movement. Regularly inspect and restack boards to distribute pressure evenly.

Should pressure-treated wood be stored differently in cold weather?

Pressure-treated lumber is more resistant to moisture and decay but should still be stored off the ground and covered to prevent surface frost or ice buildup.

Final Thoughts

Canadian winters are tough on wood, but with a bit of care and planning, your lumber can stay in perfect condition until you are ready to build again. Remember that wood always responds to its environment, so stability and airflow are your best tools for protection.

Whether you are storing hardwoods for fine furniture or framing lumber for your next deck, the right storage approach will save time, money, and frustration in the spring. Windsor Plywood offers high-quality lumber, finishes, and expert advice to help Canadian woodworkers protect their materials through every season.