Best Hardwood Options for Cutting Boards

Hardwoods are the top choice for cutting boards because they are dense, durable, and have tight grain structures that resist moisture. They also tend to be more stable and less likely to warp or dent with regular use.

Popular and Reliable Choices:

Maple (Hard Maple or Sugar Maple): Maple has been the traditional choice for generations of woodworkers. It has a light, neutral color, smooth texture, and fine grain that resists water and bacteria. It is also easy to find and affordable, which makes it ideal for first-time projects.

Walnut: A darker wood with deep, rich tones and a subtle grain pattern. Walnut is strong but slightly softer than maple, which makes it gentle on knives. It creates a high-end look and pairs beautifully with lighter woods in combination designs.

Cherry: Cherry offers a warm reddish tone that deepens over time as it oxidizes. It is fine-grained and easy to work with, and it develops a beautiful patina that tells the story of use over the years.

Beech: A pale, fine-grained hardwood that is common in European butcher blocks. It is durable, smooth, and easy to sand or glue. Beech tends to be budget-friendly without sacrificing performance.

Birch or Ash: Both are Canadian favorites that balance affordability with decent hardness. With proper finishing, they make excellent boards that hold up well under light to moderate use.

Many woodworkers mix two or three species to create contrast and visual interest. Maple and walnut, for example, look striking together and balance strength with knife-friendliness.

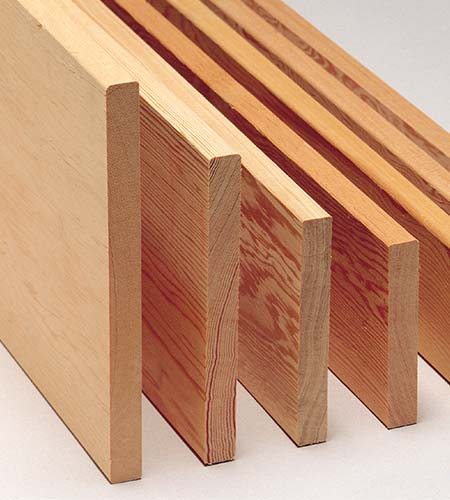

End Grain vs. Edge Grain: Which Is Better

When choosing your wood, it’s important to understand how the grain orientation affects your board’s performance and longevity. The two most common construction types are end grain and edge grain, each with its own advantages.

End Grain Boards:

These boards are made by turning the wood so the cut ends of the fibers face upward. When you slice into the surface, the knife passes between the fibers instead of cutting across them. This makes end grain boards more durable and self-healing. They are often found in professional kitchens because they are gentle on knives and last for decades with proper care.

Edge Grain Boards:

These boards use the long, side edges of the wood as the cutting surface. They are simpler to make, require fewer glue joints, and display a clean, linear grain pattern. While they are less expensive and easier for beginners, edge grain boards show knife marks more quickly and may need more frequent maintenance.

| Feature | End Grain | Edge Grain |

|---|---|---|

| Knife Friendliness | Excellent | Good |

| Durability | High | Moderate |

| Appearance | Checkerboard pattern | Straight grain lines |

| Cost | Higher | Lower |

| Maintenance | Regular oiling | Easier upkeep |

If you are making your first cutting board, edge grain is a great starting point. If you want a more advanced, long-lasting project that feels professional, go for end grain.

Woods to Avoid for Cutting Boards

Not all wood is safe for food contact. Some species are too soft, too porous, or contain natural oils and toxins that make them unsafe for kitchen use.

Avoid These Woods:

- Pine, Fir, or Spruce: These softwoods are resinous and prone to deep knife marks, which can trap bacteria.

- Cedar: While aromatic, cedar’s natural oils can transfer to food and cause unpleasant tastes.

- Oak: It is strong but has large open pores that hold moisture and bacteria.

- Exotic Woods (like Rosewood, Wenge, or Purpleheart): Many of these contain compounds that can cause allergic reactions or are not food-safe.

Stick to closed-grain hardwoods that are proven safe and durable. When in doubt, ask your local Windsor Plywood expert for advice on food-grade lumber suitable for cutting boards and countertops.

Factors to Consider When Choosing Cutting Board Wood

Every kitchen is different, and so is every woodworking setup. Before selecting your wood, think about how and where your board will be used, stored, and maintained.

Checklist for Choosing the Right Wood:

- Hardness: The ideal hardness is between 1,000 and 1,600 on the Janka scale. Woods that are too soft will dent easily, while very hard woods can dull knives.

- Grain Structure: Choose tight, closed-grain woods that resist absorbing water.

- Stability: Pick woods that hold their shape even in humid or fluctuating kitchen environments.

- Workability: Some woods are easier to cut, sand, and glue than others.

- Food Safety: Always verify that your chosen species is non-toxic and safe for food contact.

- Aesthetics: Select tones that match your kitchen or project style. Combining different species can create a unique, custom look.

- Availability: Locally sourced wood often performs better in Canadian climates and supports sustainable forestry practices. Find your store

How to Maintain Wooden Cutting Boards

Once your cutting board is built, maintenance is what keeps it looking beautiful and performing well for years. A well-cared-for board can outlast plastic or glass alternatives by decades.

Maintenance Routine:

- Clean After Each Use: Wash with mild soap and warm water, then dry immediately with a towel. Do not soak or put in the dishwasher.

- Disinfect Periodically: Wipe with white vinegar or a lemon-and-salt mixture to remove bacteria and odors.

- Oil Regularly: Apply a generous coat of food-safe mineral oil or butcher block conditioner once a month, or more often if the surface looks dry.

- Seal with Wax: A blend of beeswax and mineral oil adds protection against moisture and brings out the wood’s natural luster.

- Sand as Needed: If your board becomes rough or stained, lightly sand with fine-grit paper and reapply oil.

DIY vs. Store-Bought Cutting Boards

Building your own cutting board is one of the best beginner-friendly woodworking projects. It teaches important skills like planing, glue-up, and finishing, and the final result is both functional and beautiful. However, buying a professionally made board also has its advantages.

DIY Cutting Boards:

- Fully customizable in size, shape, and species

- Affordable and rewarding for hobbyists

- Teaches practical woodworking skills

Store-Bought Cutting Boards:

- Ready to use immediately

- Professionally finished and consistent in quality

- Ideal for those who prefer convenience

Whether you build or buy, start with the right wood and finish. Explore hardwoods, glues, and food-safe finishes to get the best results.

Best Wood for Cutting Boards – Frequently Asked Questions

What is the best hardwood for a cutting board?

Hard maple is the most reliable choice. It offers an ideal balance of hardness, stability, and food safety. Walnut and cherry are also excellent options for more decorative designs.

Is cherry wood safe for cutting boards?

Yes. Cherry is completely food-safe and develops a rich patina with age. Many woodworkers use it for accent stripes or full cutting boards.

How often should I oil a wooden cutting board?

At least once per month, or whenever the surface feels dry. Regular oiling helps prevent cracking and keeps moisture from soaking into the wood.

What’s the difference between a butcher block and a regular cutting board?

A butcher block is usually thicker and made with end grain construction, which makes it more durable and self-healing. Regular cutting boards are thinner and often use edge grain for a smoother look.

What type of cutting board is best for meat?

End grain boards made from maple or beech are ideal. They are strong, easy to clean, and resist knife marks, which helps prevent bacteria buildup.

Final Thoughts

Making your own wooden cutting board is more than a woodworking project. It is an opportunity to combine craftsmanship, creativity, and practicality. The right wood will not only enhance your kitchen but also tell a story every time you use it.

Whether you choose maple for its classic simplicity, walnut for its elegance, or cherry for its warmth, your board can last for generations with the proper care. Windsor Plywood is proud to support Canadian woodworkers with high-quality hardwoods, finishes, and guidance for projects just like this one.

Start with the right wood, treat it well, and you’ll have a cutting board that becomes part of your home’s history.